100 Years of Power Generation

One-hundred years of active service … a claim few other generating stations could make! I was able to tour this gem of history while it was owned by Canadian Niagara Power during three visits (twice while it was still operating), one an “Open Doors Niagara” event in 2003 in which numerous places of historical significance in the Niagara area opened their doors for tours, the second visit an IEEE sponsored event in 2004, and a third visit a private tour in 2008. As an engineer I was absolutely taken back with what I saw.

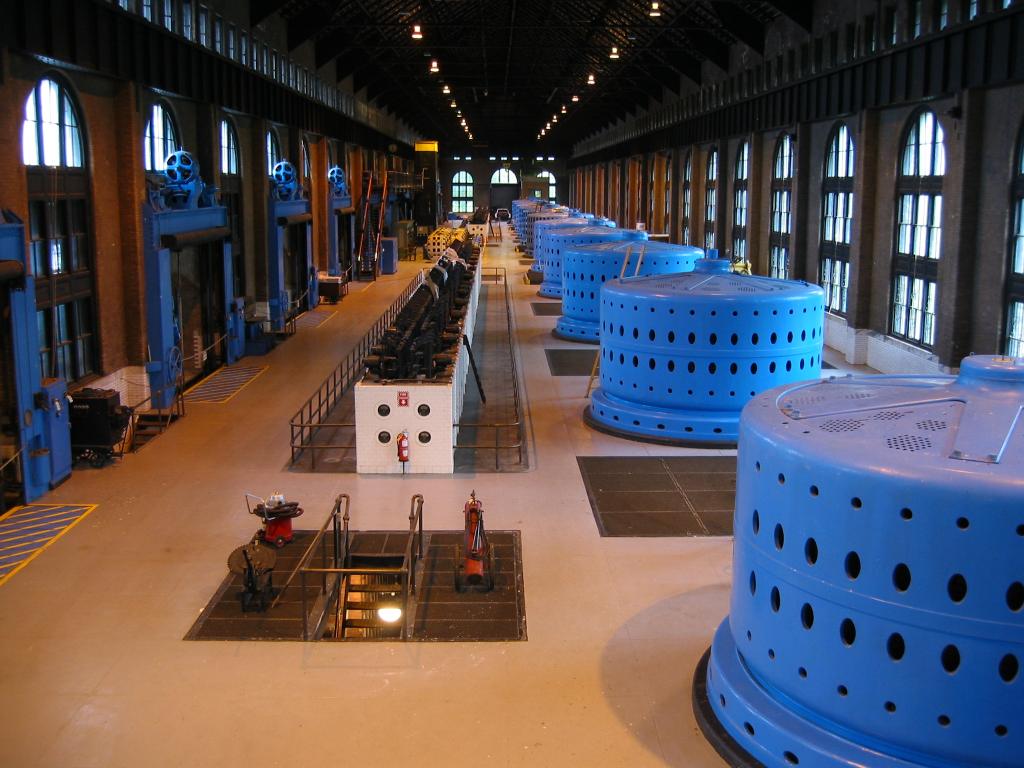

Truly, walking into this place was like walking back in time 100 years to the dawn of the age of electricity where few places in the world had electric lights. Electricity, in those days, was ‘The Magic Medium’ and to many people, still accustomed to using coal-oil lamps in their houses for lighting, it probably seemed like magic. The generating station itself, built of limestone and featuring Italian marble and polished brass everywhere, speaks to an era where electricity was not simply a matter of utility – it was a new and expensive commodity and was treated as such. The mixture of technology, both old and new, architecture, and a total amazement at what they could do with manual labour and steam-powered excavators led me to write this page to share it with you. Enjoy!

See what has become of the station which is now the Niagara Parks Power Station attraction.

Introduction: The Rankine Station

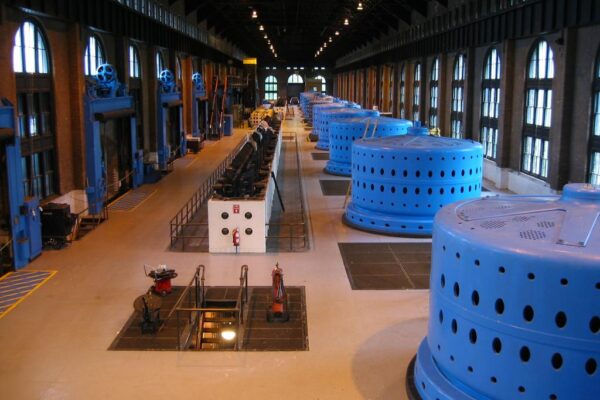

The Rankine station was, until 2006, one of the few 25Hz powerhouses surviving in the world. Until its shutdown, it was actively operating supplying industries in Niagara, on both sides of the border, with 25Hz power. During it’s heydey, the plant was licensed to produce 102,500 hp (about 76MW) via it’s eleven generators. In the early 2000’s, the load for the plant, normally, was 40MW with 30MW supplied to Stelco in Hamilton for arc furnaces and 10MW to Washington Mills to operate furnaces there. Numerous small customers also utilized 25Hz power for everything from theatre movie projectors to elevators. In New York state, an estimated 85 customers (in 2004) still utilized 25Hz power. The future of 25Hz power was, of course, limited since the vast majority of loads in the region (both in Canada and in the US) were converted in the 1950’s to 60Hz power. By 2009, the supply of 25Hz power was to cease entirely. Still, the design of the plant provides insight into what could be accomplished with good engineering and relatively simple control systems.

The engineering that went into the plant was second-to-none (why else would it have lasted 100 years?). Careful thought was put into every aspect of the plant including the water supply (featuring a forebay designed to eliminate the problem of ice buildup), the basic electrical system (using 3-phase, new at the time and unproven in North America), the mechanical systems (massive vertical shafts supported by bearings with backup oil feed and backup water-cooling supply), and the control systems (using methods to synchronize alternators which were new at the time). Many parts of the plant exhibit cutting-edge engineering for their day.

This station was by no means the first to harness the power of Niagara Falls … many previous attempts were made on both sides of the river … but it was, at the time, the most significant given the immense size of the project as well as the fact that it used AC allowing the current produced at this facility to be transmitted over great distances. While it looks antiquated now, in 1905 it was state-of-the-art and solved many of the engineering problems associated with earlier attempts to generate and transmit power on a large scale.

Background: Early Power Development

The earliest attempt at centralized power production (on a large scale) was by Thomas Edison in New York city in 1882. Steam engines drove relatively low-voltage DC generators primarily for lighting purposes. DC current cannot be transmitted for distances of more than a few miles so Edison envisioned a series of power plants located in and around large cities. A replica of one of Edison’s coal-fired steam generating plants (the original, from Detroit, MI, circa 1888) sits in Greenfield Village in Dearborn, Michigan. No surprise, then, that earliest attempts to harness the power of the falls considered the use of DC current (endorsed by Edison) but this would have prevented distribution to Buffalo, 22 miles away, a large market for power (industrialized and with a population of 250,000 at the time). The limits of DC were soon realized, even for use within cities (imagine generating stations literally miles apart) and in 1892 Buffalo achieved the honour of being the first major city in North America to use AC power (Similar developments using AC power and long-distance transmission occurred in Germany in 1891). Steam plants, similar to Edison’s DC plants in New York City, generated AC current for lighting (and so fewer were required since this power could be transmitted much further). The application of AC in North America began, in fact, in the Niagara area but long-distance transmission from the falls was still a dream until 1896.

Henry Ford idolized Edison and with good cause: Ford was an employee of Edison’s at the Detroit Station in the 1890’s, eventually becoming chief engineer. Ford built his first car, the ‘quadricycle’ while still employed at the plant.

Power Production in Niagara

Development of power projects in Niagara began on the American side of the falls – the first major development began in 1890 when William Birch Rankine, a lawyer in New York, attracted investors and formed the Niagara Falls Power Company. The Adams power plant was the result and it was, in many ways, a prototype for the Rankine plant. By 1895 the first generators of 5000hp produced AC at 2200 Volts and one year later three generators were running producing power that was transmitted to Buffalo. This would be expanded, later, to two plants with ten active generators each. Many engineering details, including the final adoption of the three-phase AC power system (the Adams plant originally generated two-phase power), designed by Nikola Tesla (of Tesla coil fame) were finalized in this project and the system became the prototype for electricity distribution projects worldwide. As far as standardization went, though, 25Hz – as employed on many of the earlier developments in Niagara – was adopted at the Adams plant. In the Niagara area, power was primarily required for industrial usage (e.g. furnaces) as well as motor power – lighting was a secondary concern so the fact that 25Hz electric light flickered was of no particular consequence since this was only a small usage of the total power output. The original problem (leading to the adoption of 25Hz) stems from the fact that the turbines at the Adams plant were built before the adoption of AC was solidified – in fact at the time these turbines were installed it was not clear whether they would be used for the production of electric power at all or pneumatic (compressed air) power! Electricity was indeed a new thing in the late 1800’s and it was not certain at all that whether it would become ‘universal’ or simply another passing fad.

The original turbines at the Adams plant, with their massive shafts, were designed to operate at 250 rpm (again, quite likely to drive pneumatic compressors, not electrical generators) and so 12 pole electric generators were envisioned which produced 25Hz to take advantage of the already-installed (slow) turbines. While many other places throughout North America adopted 60Hz as a standard (which was endorsed by the Westinghouse company, a prime supplier of AC machinery), Niagara’s largest power project to date was going 25Hz. Aside from the ability to utilize a 250 rpm turbine, 25Hz was chosen as it allowed power to be interchanged with the existing (although fledgling) power system developing on the US side of the river and technologically, it allowed easier synchronization between generators. This set the ‘standard’ in Niagara which would remain so until half-way through the 20th century when the introduction of fluorescent lighting (which flickered much worse on 25Hz than incandescent lamps) and home electronics was the final blow to the standard. On the US side of the falls, the Adams plant (owned by the Niagara Falls Power Company) generated two-phase AC and delivered 11000 volt AC current (stepped-up for transmission) to the large Buffalo market via a 22 mile long route in 1896. It was, at the time, the most ambitious power project of its type. Buffalo, site of the Pan-American exhibition of 1901, was indeed power-hungry and the Adams plant would not provide an adequate supply of power for long – the Rankine plant to be built on the Canadian side was envisioned as being the prime supplier. The Adams plant was closed permanently in 1961 and water diverted to the more efficient Robert Moses plant just North of the falls.

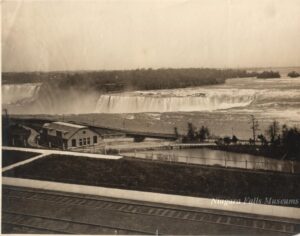

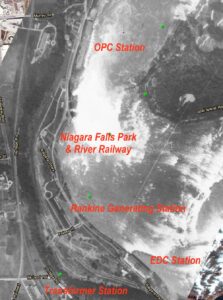

While power development proceeded on the American side of the falls, the first power generated on the Canadian side was in 1892 for the Niagara Parks River Railway. Three small turbines generated enough DC current (about 2 Megawatts) to run the electric trolleys which carried tourists through the area. The building was just to the north of the CNP plant outlined on this page and the plant was decommissioned in 1932 when the trolleys were removed and “the Boulevard” (the Niagara Parkway) was built to carry automobile traffic. It was demolished and today the main bus stop for the people-mover bus, just outside table rock, stands on that very site. The significance of this plant will be illustrated below as well.

In the Niagara area, there is one older plant than the Rankine, the DeCew Falls plant located on the Niagara escarpment in St. Catharines. Operating in 1898, this plant produced AC current at 66.6 Hz (a first) and supplied power to Hamilton. The plant was bought by Ontario Hydro in 1930 and converted to 60Hz operation. It still operates today making it the oldest power plant in Niagara.

The Rankine Story

The Rankine story really begins in 1889 with the formation of the Niagara Falls Power Company in New York – the primary interests in the US Adams plant. Initial plans for this company were to produce electric power on the US side of the falls, eventually at two plants (the Adams generating stations). Logically, wanting to move into production of power on the Canadian side of the falls, a spin-off company called the Canadian Niagara Power (CNP) Company was formed in 1892. A site was leased from the Niagara Parks commission – eager to see development of the falls like that occurring on the American side – upon which the Rankine generating station was to be constructed, for $25000 per year (in 1892 dollars !). The agreement, designed to stimulate power production on the Canadian side, stipulated that construction of a power plant must begin by 1897 and by 1898 production of 25000 horsepower must commence.

Enter the Niagara Falls River Railway plant (above). In 1895 CNP signed an agreement with the railway company allowing the railway company to sell surplus power for three years after which CNP would supply power to the railway. Prospective customers of that power included the Niagara Falls Electric Light Company and the Carmellite Fathers Hospice. By 1897 it became evident that CNP could not meet the deadline for development as the American arm of the company wanted to complete the Adams plant first (from which transmission of power to Buffalo began in 1896). The Adams plant supplied two-phase 2200V local service as well as three-phase service to Buffalo via 11kV lines (two-phase power, produced by the generators, was converted to three-phase by a ‘Scott Transformer’ and sent to Buffalo that way). Completion of the Adams plant first allowed the working-out of technological ‘bugs’ like lightning arrestors and switchgear before starting construction of the Canadian plant. While technology for the American plant was developed ‘on the fly’, as evident from the use of 25Hz generators to take advantage of already-installed turbines, it was hoped that the Rankine plant would be planned better from the beginning (although 25Hz was still to be used here since it was now ‘standard’ in Niagara). In a stop-gap measure CNP proposed that it install more generating equipment into the railway generating station allowing CNP to fulfill its contract. Only two 425 hp generators were installed with an excess capacity of 300-500hp available for customers. The railway plant was now generating both AC power at 2400V and DC power for the railway. It was the first plant in Queen Victoria Park and an agreement with the government of Ontario allowed CNP to continue its monopoly at this time.

Not surprisingly, local officials in Niagara Falls were upset at the apparent lack of (promised) investment in power generation – the whole idea of the agreement in the first place was to develop the Canadian side of the falls into a major power production center, with the ultimate goal of providing power to the large city of Toronto. By 1899 it was obvious that CNP could not supply power to Toronto (the CNP had not even started construction of the Rankine plant) and CNP’s monopoly to produce power at the falls was lost allowing other companies to produce power. Not surprisingly a great deal of politics were involved. In all fairness to CNP (and the parent Niagara Falls Power Company), the intent was to complete power projects on the American side first to ensure capital was not spread too thinly. There were also enormous technical difficulties to overcome in the system of transmission of the power to the intended loads in Toronto – sending power from Niagara to Buffalo is one thing (and was, at the time, a milestone), but Toronto is considerably further away.

Things got worse for CNP when the railway powerhouse caught fire in 1899 halting generation of all power (which, by now, fed the Carborundum company in Niagara Falls as well). CNP was forced to import power from the US via cables across the upper bridge across the river.

Buffalo was always seen as the primary market for Niagara power, though. The site of the 1901 Pan-American exhibition, Buffalo was fed from the Adams plant early in the century. To help feed the power-hungry city, power from the railway plant on the Canadian side was fed via cables along the upper arch bridge in Niagara Falls was sent to the US side. 1000 hp of three-phase power at 2200 volts was sent across the bridge but that, too, was not enough to satisfy the needs of the growing city … the Rankine plant would hopefully fill that need soon.

Buffalo was always seen as the primary market for Niagara power, though. The site of the 1901 Pan-American exhibition, Buffalo was fed from the Adams plant early in the century. To help feed the power-hungry city, power from the railway plant on the Canadian side was fed via cables along the upper arch bridge in Niagara Falls was sent to the US side. 1000 hp of three-phase power at 2200 volts was sent across the bridge but that, too, was not enough to satisfy the needs of the growing city … the Rankine plant would hopefully fill that need soon.

The Rankine plant, started in late 1901 and generating power for the first time in early 1905 (but not fully complete for many more years), was the first major power development on the Canadian side of the falls and at the time, the largest generating plant with the most advanced technology available. It would soon be joined by other power plants, though …

Competition … even before the race had begun!

With the monopoly on power production gone, other major power projects around the area included the Electrical Development Company’s (aka the “Toronto Electric Company”) generator just to the south of the CNP plant on the other (water) side of the parkway. Ready at the end of 1906 (after the Rankine plant was already producing power), this plant generated 75 Megawatts of power destined for Toronto. Water drawn from the river powered turbines in the station and was discharged through a tunnel (actually, two tailrace tunnels) leading behind the horseshoe falls. The tunnels were built of concrete rings so that as the falls recedes, these rings would fall into the river below instead of leaving a concrete structure protruding from the falls! This station was decommissioned in 1973 but the building is still intact on the west bank of the Niagara river today. The building is currently unsafe with portions of the roof collapsed due to neglect. In past years, parts from this old generating station have been scavenged for use at the Rankine plant as spares.

With the monopoly on power production gone, other major power projects around the area included the Electrical Development Company’s (aka the “Toronto Electric Company”) generator just to the south of the CNP plant on the other (water) side of the parkway. Ready at the end of 1906 (after the Rankine plant was already producing power), this plant generated 75 Megawatts of power destined for Toronto. Water drawn from the river powered turbines in the station and was discharged through a tunnel (actually, two tailrace tunnels) leading behind the horseshoe falls. The tunnels were built of concrete rings so that as the falls recedes, these rings would fall into the river below instead of leaving a concrete structure protruding from the falls! This station was decommissioned in 1973 but the building is still intact on the west bank of the Niagara river today. The building is currently unsafe with portions of the roof collapsed due to neglect. In past years, parts from this old generating station have been scavenged for use at the Rankine plant as spares.

In 1905, a plant built by the Ontario Power Company (another private concern) was opened under what is known today as table rock. The OPC unveiled its planned station in 1900 and began construction in 1902. Water from above the falls near the Dufferin islands (the gate house is just south of the Toronto generating plant) is carried via two large-diameter pipes to the plant just below the falls which produced 25Hz AC current like the CNP plant on this page. Two large surge tanks, one still intact today with the battery of lights which illuminate the falls each night mounted atop it, were used to smooth-out water flow as usage in the plant below changed. This plant has been mothballed by Ontario Hydro (which took over the plant early in the century) – the original transformer house for this station sat on the site now occupied by the casino.

Shortly after the first decade of the century new power projects were declared to become public property and water rights were no longer granted to privately-owned concerns. All further development of hydro-electric projects, including the two huge Sir Adam Beck stations north of the falls in Queenston, was completed by the government-owned Ontario Hydro Company. The DeCew, Toronto Power, and Ontario Power plants were eventually bought by Ontario Hydro – only the Rankine remained as a privately-owned power plant.

While the delay in building the Rankine plant proved costly to CNP, in terms of losing its monopoly on power production, it also gave them time to overcome technical obstacles. By 1902, a year after construction of the plant began, the problem of transmission of power (to Toronto) was solved. Based on work done at the US Niagara Falls Power Company plants, transmission was accomplished by stepping-up the voltage to 60kV using transformers built by the Canadian General Electric Company (Remember, too, that this was a scant 14 years after Edison’s Pearl St. DC plant so AC technology had developed an amazing amount during this short time period! The fact that GE built the transformers is also ironic given that one of the founders of GE, Edison, was adamantly opposed to the use of AC). The transformer house for the Rankine plant still stands today atop the bluff behind Victoria park – a separate transformer house was necessitated by the agreement with the Parks commission that prohibited unsightly overhead wires. On January 2, 1905 the Rankine plant began producing power with only two 10000hp alternators. Those alternators, originally pegged at 5000hp each, were also subject to improvements and were upgraded to 10000hp each by the time they were installed. Power was utilized by both Canadian customers as well as in Buffalo as the use of AC current allowed transmission over great distances – the Canadian route to Buffalo was advantageous since it was only 16 miles long and hence shorter than the US route. Power was fed to Buffalo via lines crossing the Niagara river at Fort Erie, Ontario.

While two generators were producing power in 1905, the rest of the plant was still under construction. The plan was to start the North end of the plant first (which included the first two generators) which included the wheel pit and the power house then extend it to the south. The north end of the plant, then, housed a temporary switchboard as well which sat above the breakers inside the hall housing the generators. As the plant was extended (with the power house building being essentially complete in 1913 however with the last of the eleven generators being installed in 1924), the central control room was now located in the center of the building (it is the same control room seen today in the photos below).

The total cost of the completed plant was $5.2 million (in 1924 dollars).

Construction (1900-1910)

The construction of the Rankine was an amazing undertaking at the time. It involved the construction of a cofferdam at the river (to keep the river water out during construction), excavation of a forebay, construction of the powerhouse itself to house all eleven generators, excavation of the wheel pit where the turbines would be housed (in the bottom, with mechanical power transmitted to the generators above via long vertical shafts), a 2200-foot long tailrace tunnel to bring water back to the Niagara river below the falls, and a transformer building which, for esthetics, would be built outside of the park some distance away. All of these parts would be started simultaneously as they would all be required. The photos below were provided from the CNP archives.

Cofferdam

Before any excavation could take place, a large cofferdam was required to contain the mighty Niagara river. Wood forms were erected along with a large amount of stone to hold back the raging river. Obviously some leakage occurred and steam-driven pumps were required to keep the area dry enough to excavate. The cofferdam was in place from the start of construction in late 1901 until late 1904 when it was removed to flood the forebay.

Before any excavation could take place, a large cofferdam was required to contain the mighty Niagara river. Wood forms were erected along with a large amount of stone to hold back the raging river. Obviously some leakage occurred and steam-driven pumps were required to keep the area dry enough to excavate. The cofferdam was in place from the start of construction in late 1901 until late 1904 when it was removed to flood the forebay.

Forebay

Excavation of the forebay began soon after the cofferdam was in place. An enormous amount of earth was removed to make the bay 14 feet in depth. The photo on the left, from October of 1902, shows the pit along with horse-drawn carts used to carry the material away once cubic yard at a time.

Excavation of the forebay began soon after the cofferdam was in place. An enormous amount of earth was removed to make the bay 14 feet in depth. The photo on the left, from October of 1902, shows the pit along with horse-drawn carts used to carry the material away once cubic yard at a time.

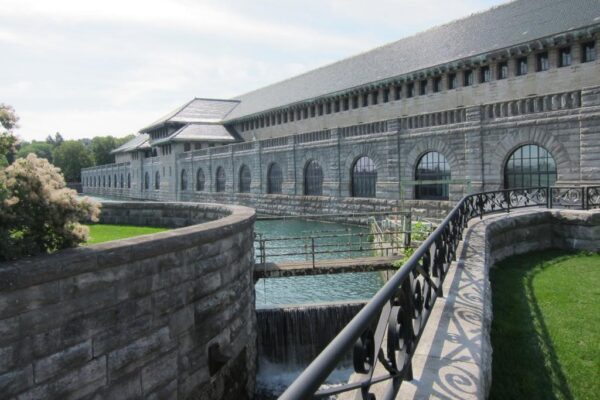

Two years later and the pit was complete. Walls of quarried stone were erected around the bay and a bridge was built to span the bay allowing the tourist railway to pass over. The bridge still stands today but now the Niagara Parkway four-lane road passes over it.

Not evident here is the engineering that went into designing the forebay including an ice sluice through which ice returned to the river to go over the falls. Water level in the forebay were higher than submerged arches through which water entered the plant so ice was trapped in the forebay allowing it to be broken-up and released.

The entire plant was engineered to last at 100 years and so massive quarried stone was used to line the forebay – the performance of this approach was well known and there was some doubt that the relatively new technique of poured concrete would not last. This added time and cost to the construction of the plant.

Six months after the photo on the right was taken, the forebay would be flooded allowing water from the river to enter the plant.

Wheelpit

Excavation of the wheelpit began with removal of the surface earth to the rock below. This was accomplished mainly with manual labour and horse-drawn carts.

Excavation of the wheelpit began with removal of the surface earth to the rock below. This was accomplished mainly with manual labour and horse-drawn carts.

By April of 1902 rock was hit and blasting and drills would now be required. The photo on the right is of the north end of the wheelpit which was started first … the south end would not be started for some time.

Tailrace

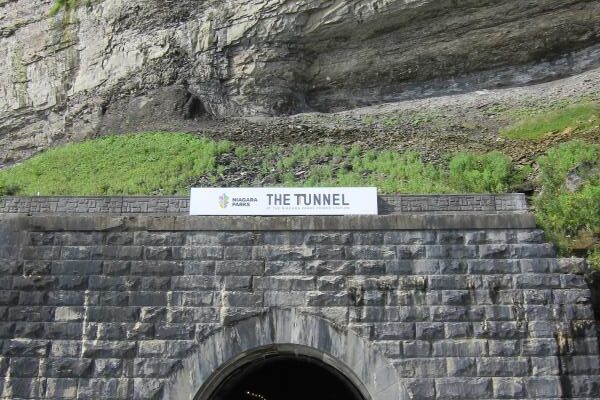

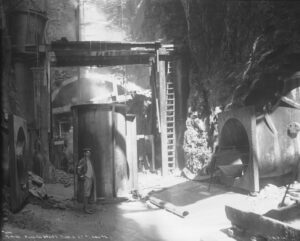

Once water exited the turbines through draft tubes, it poured into a 2200 foot long tunnel to return to the river just below the falls. A shaft was first sunk in the middle of what would become the tunnel and excavation occurred both towards the wheelpit (or at least where the wheelpit would be) and towards the falls. Not a small feat by any means! It was lined with brick and concrete and was ready in early 1904, well in time for the wheelpit to be sunk on top of it and to handle water from the newly installed north turbines.

Once water exited the turbines through draft tubes, it poured into a 2200 foot long tunnel to return to the river just below the falls. A shaft was first sunk in the middle of what would become the tunnel and excavation occurred both towards the wheelpit (or at least where the wheelpit would be) and towards the falls. Not a small feat by any means! It was lined with brick and concrete and was ready in early 1904, well in time for the wheelpit to be sunk on top of it and to handle water from the newly installed north turbines.

Turbines

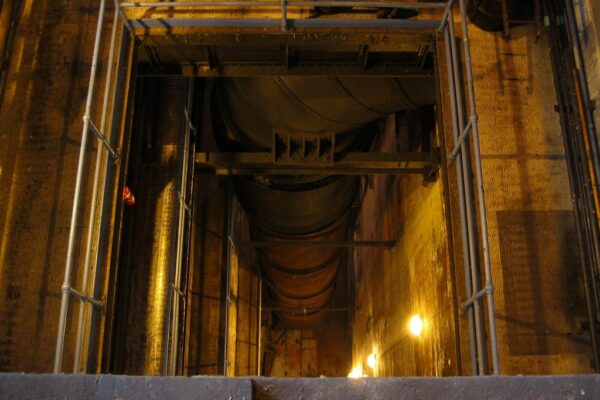

Water in the forebay enters the plant through submerged arches. This allowed ice to be separated from the water (ice which then flowed back to the river via a sluice to the north). Water then enters the forebay inside the plant where it passes through trash grates to exclude debris, through massive head gates, and enters pentstock tubes ten feet in diameter falling 130 feet to the turbines below.

Water in the forebay enters the plant through submerged arches. This allowed ice to be separated from the water (ice which then flowed back to the river via a sluice to the north). Water then enters the forebay inside the plant where it passes through trash grates to exclude debris, through massive head gates, and enters pentstock tubes ten feet in diameter falling 130 feet to the turbines below.

Turbines were five feet in diameter and rated at 10000hp (12500hp for those built after unit #5), double-runner, which were fed from the outside via a ring valve to regulate water flow and hence speed. Water then discharged to the inside to the tailrace tunnel below via draft tubes to return to the river.

Powerhouse

The powerhouse was built on a massive foundation around the wheelpit – massive to support the huge generators it would house. It was built of a steel frame and clad with cut stone to look regal within the park.

The powerhouse was built on a massive foundation around the wheelpit – massive to support the huge generators it would house. It was built of a steel frame and clad with cut stone to look regal within the park.

Started in 1904 once the wheelpit under it was complete, it was built from the north downward so that when it opened in 1905, it was only half its final length at 296 feet (big enough to house only five generators).

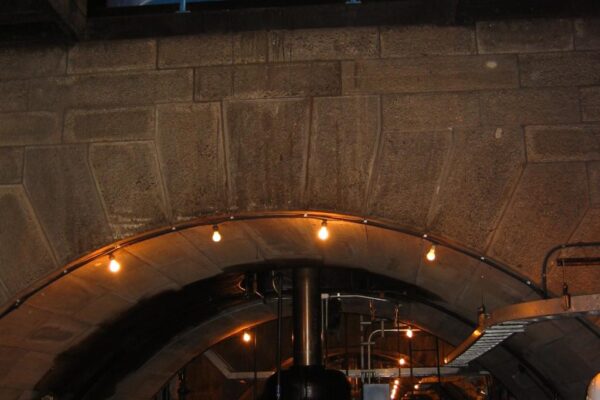

Huge arches under the floor of the powerhouse would hold the weight of the generators as well as the high-pressure oil-fed thrust bearings that held the massive 90-ton shaft connected to the turbines below.

Huge arches under the floor of the powerhouse would hold the weight of the generators as well as the high-pressure oil-fed thrust bearings that held the massive 90-ton shaft connected to the turbines below.

The powerhouse opened in 1905 with only two generators installed. More units would be added during the same year. Since the powerhouse was incomplete, a temporary switchboard was built above the breakers on the shop floor.

By 1910, the powerhouse was still incomplete and held only six generators but it was generating electricity and making money. It wouldn’t be until 1913 that the powerhouse building was essentially complete and until 1924 when the last of the eleven turbines would be installed and running. When the building was completed, the control room was moved upstairs. The new state-of-the-art control room featured panels made of marble – they would truly last 100 years.

By 1910, the powerhouse was still incomplete and held only six generators but it was generating electricity and making money. It wouldn’t be until 1913 that the powerhouse building was essentially complete and until 1924 when the last of the eleven turbines would be installed and running. When the building was completed, the control room was moved upstairs. The new state-of-the-art control room featured panels made of marble – they would truly last 100 years.

Power generated was destined for three locations. Power destined for Niagara Falls, USA (relatively local), was carried at 12kV via underground cables to the upper arch bridge where is made its way across the river to the US side. Power destined for local Canadian loads, as well as Buffalo, was sent to a transformer station …

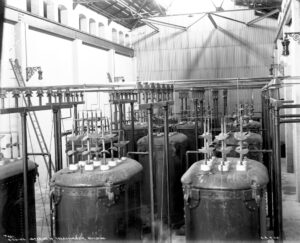

Transformer House

The agreement with the parks commission stated that the transformer house and associated overhead wiring was not to be housed in the park for aesthetic reasons. Power generated at 12kV was hence sent to a transformer house at the top of the escarpment via an underground duct. There, it was transformed to 2200V for local loads in the city of Niagara Falls, and to 22000V for transmission along the long lines to Fort Erie and Buffalo where the majority was destined. High-voltage transformers were water-cooled with water drawn from the river. A large tank beside the transformer house ensured a backup supply of gravity-fed cooling water should the pumps fail. Again, this illustrates the care with which the system was designed and the attention paid to detail.

The agreement with the parks commission stated that the transformer house and associated overhead wiring was not to be housed in the park for aesthetic reasons. Power generated at 12kV was hence sent to a transformer house at the top of the escarpment via an underground duct. There, it was transformed to 2200V for local loads in the city of Niagara Falls, and to 22000V for transmission along the long lines to Fort Erie and Buffalo where the majority was destined. High-voltage transformers were water-cooled with water drawn from the river. A large tank beside the transformer house ensured a backup supply of gravity-fed cooling water should the pumps fail. Again, this illustrates the care with which the system was designed and the attention paid to detail.

Transformers were important: Now that you can generate tens of thousands of horsepower of electricity you need to get it to market – and that market was always envisioned as being Buffalo NY. The Canadian route ran along the Niagara river crossing over it at Fort Erie, Ontario. This was substantially shorter at 16 miles than the US route.

Like the powerhouse, the transformer house was built in stages with enough capacity for opening day and the capability to expand as more transformers were needed. The transformer house still stands today and can be seen at the intersection of Marineland Pkwy and Portage Rd.

The Operating Plant (2000-2010)

The Hydraulic System of the Rankine Plant

We begin by examining the hydraulic system consisting of water gates, massive pipes to carry the flow, and turbines.

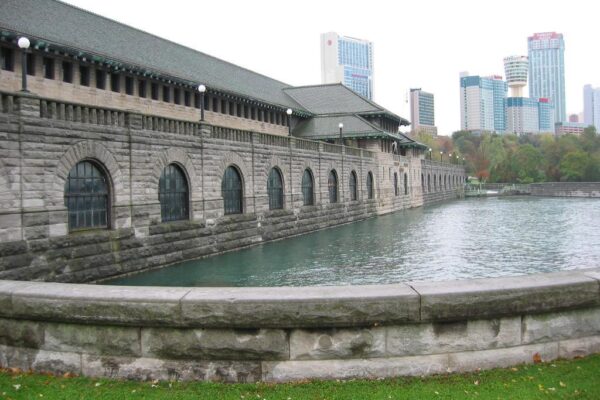

Water from the Niagara river enters the forebay to the plant just above the horseshoe falls. The Niagara Parkway, which runs parallel to the Niagara river, passes over a bridge across the entrance to the forebay. The original placement of the Rankine plant was on what was known in 1900 as Cedar island – this was to take advantage of the natural flow of water towards the island, on which the plant was to be built. Water channels behind the island were filled-in and what was once an island became a part of Queen Victoria park. The five-arch bridge was originally designed to carry the electric trolley cars used by the Niagara Falls Park and River Railway Company to carry tourists around the falls. Water is channeled into this entrance by a submerged weir visible only as a change in the current of the water.

Water then slows and settles in the forebay, to a speed of six feet per second, and deeper water in the forebay, free from ice, is drawn into the powerhouse through a series of submerged arches. Ice, floating atop the pond, is swept away down a small canal to re-enter the river.

Ice has always been the achilles-heel of generating stations at Niagara and the Rankine plant used an icebreaker boat and even dynamite to clear the forebay from ice build-up. One of the advanced features of the forebay was indeed the ice sluice which routed broken-up ice back to the river where it went over the falls. Other plants, notably the OPC plant at the base of the falls, were considerably more susceptible to ice problems.

The architecture of the plant with its huge arches and limestone construction, hardly detracts from the esthetic beauty of the falls. Huge copper doors on the other side of the plant elude to the grandeur of the building and the status electricity once had in the dawn of this era.

Mechanical System and Generators

Once water reaches the turbines 130 feet below, it spins turbines in the ‘wheel pit’. Mechanical energy is transferred to the generators in the powerhouse above via long vertical shafts. Supporting these heavy shafts are immense oil-lubricated and water-cooled bearings right under each generator. As well as the mechanical task of transferring energy, the speed of the turbines must also be regulated – this was accomplished by a ‘spinning ball’ governor which opened or closed a ring valve on top of each turbine as required to regulate the speed of the shaft to 250rpm. Later, the control system was updated to an electronic system which accomplished the same task (but without the mechanical complexity of the early governors).

The Control System

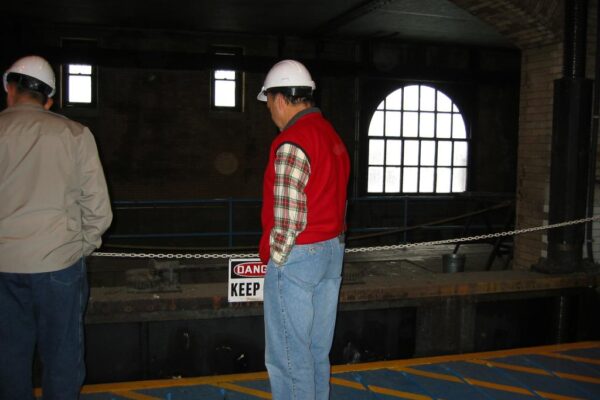

Of course there is more to power generation than simply spinning an alternator … there is a huge issue around controlling it. First and foremost, before AC alternators are placed in parallel on a grid to generate power they must be synchronized both in output voltage and in phase. To this end, power stations often use elaborate computerized controls but not 100 years ago! This particular plant is a unique blend of old and new technology with several generating units utilizing modern controls and others relying on the operator at the plant to manually synchronize the alternators.

To place a generator on the bus (i.e. ‘online’), the speed of the generator is first set to 250 rpm via the governor. Next the output voltage is matched to the bus by varying the (DC) rotor current. Finally (and this is a key step), the phase of the generator must be matched to the phase of the bus to which it will be connected. Early approaches to synchronize generators used electric lamps to indicate relative phase difference (made easier with the slow line frequency) however the Rankine station (as seen in the early 2000’s) used a ‘synchro-clock’ is used to indicate phase difference between the generator and the bus. A special six-pin plug is inserted into the socket on the control panel for each generator and the clock lights-up. Rotation of the clock hand indicates relative phase difference. The generator is sped-up or slowed-down slightly until the phase difference is zero (the hand of the clock indicates 12:00) at which point the operator closes the breaker connecting the generator to the bus. Closing the breaker too early or too late (when synchronization has not been achieved) results in a huge electrical arc in the breaker as well as mechanical torque on the generator mounts that could be felt throughout the building).

Decline of the Plant

During the 1950’s all of Ontario was systematically converted from 25Hz power to 60Hz power. Trucks came through each neighbourhood converting motors to the new current. Aside from the fact that lights flickered noticeably at 25Hz (and don’t at 60Hz), transformers and other equipment operating at 60Hz are much smaller (this is also the reason why aircraft use 400 Hz systems – the size and weight of electrical equipment are reduced drastically over 60Hz). My parents had an electric fan from the early 50’s with a ’25Hz’ label on it. A second label states that the motor was rewired for 60Hz. Of course only motors were affected by the change and in the 1950’s there were a lot fewer motors and appliances than there are today. The photo to the left shows a truck driving down a street picking up appliances such as washing machines for conversion.

During the 1950’s all of Ontario was systematically converted from 25Hz power to 60Hz power. Trucks came through each neighbourhood converting motors to the new current. Aside from the fact that lights flickered noticeably at 25Hz (and don’t at 60Hz), transformers and other equipment operating at 60Hz are much smaller (this is also the reason why aircraft use 400 Hz systems – the size and weight of electrical equipment are reduced drastically over 60Hz). My parents had an electric fan from the early 50’s with a ’25Hz’ label on it. A second label states that the motor was rewired for 60Hz. Of course only motors were affected by the change and in the 1950’s there were a lot fewer motors and appliances than there are today. The photo to the left shows a truck driving down a street picking up appliances such as washing machines for conversion.

Laws written many years ago compelled power companies to continue production of 25Hz power so long as there were customers requesting it. This arrangement has lapsed and with it, the demand for the production of 25Hz power. As of 2003 there were still a number of industries using 25Hz power such as Stelco in Hamilton (for electric arc furnaces which operate more efficiently at lower frequencies) which had not yet converted to 60Hz power.

The efficiency of a power plant operating this close to the falls suffers from a much smaller drop than generating stations operating down the river (like the Sir Adam Beck stations). A larger drop yields more kinetic energy and hence power generated per gallon than a smaller drop and since there is a finite amount of water available at Niagara Falls for power generation (limited by a treaty between the USA and Canada designed to keep ample water flowing over the falls), efficient use of water resources is a prime concern nowadays.

During my visit in 2003, the plant was on ‘standby’ status and was still used, primarily on weekdays, to generate power for various industries. In addition, the plant generated power when excess water capacity was available which could not be entirely used by the other OPG (Ontario Power Generation) plants in the area such as Sir Adam Beck 1 and 2. In 2005, after 100 years of continuous power generation, the plant officially ceased generating power. Water once consumed by the Rankine is diverted to the Beck plant in Queenston, Ontario, via a third large tunnel drilled under the town of Niagara Falls (another interesting achievement – search this one on the web). CNP had signed-over its water rights to OPG and water which once flowed through the Rankine plant (as well as other two early plants at the top of the falls) now flows to the updated Sir Adam Beck plant in Queenston where it generates even more power.

During my first tour of the plant in 2003, on a quiet Sunday morning, one alternator was active and generating more than enough power for customers on the grid at that moment. On the second tour of the plant one alternator was spinning, but curiously, no water was flowing! The alternator was ‘motoring’: An alternator such as this can be run as a wound-rotor motor. Fed from the 25Hz grid (powered primarily from the large frequency-changer at the Sir Adam Beck 1 plant down the road at this time in the week), the alternator was kept ‘warm’, synchronized, and ready to operate immediately. Part of the agreement CNP had with the market operators was to be able to supply power to the grid at a moment’s notice so it was important that at least one unit always be in a ready state. I was also told that during the winter months electric current is circulated through idle alternator’s windings to keep them warm and free of condensation: 13.8kV and moisture don’t mix well! During my last visit in 2008, all generators were kept in operational condition in this manner (to preserve them from damage) …. even with the plant mothballed, CNP is still taking care of this gem!

By 2008, all generators were silent and 25Hz power, supplied via the frequency changer at Beck-1, was used to power the sole CNP client still consuming 25Hz: Washington Mills in Niagara Falls, Ontario. This power was routed through the 25Hz grid via the Rankine station which was still used as a distribution and control point for the 25Hz grid.

As of 2009, 25Hz generation ceased entirely and the 25Hz grid was slated for shutdown. As for the Rankine plant: in April of 2009 the lease on the land on which the Rankine sits was up and the plant reverted to the Niagara Parks Commission (NPC) …

For further interesting reading on the Rankine and the history of the Canadian Niagara Power Company I suggest the excellent book The Canadian Niagara Power Company Story by Norman R. Ball (Boston Mills Press, 2005, ISBN 978-1-55046-462-7).

The Niagara Parks Power Station Attraction

In the middle of the CoVid pandemic, the Niagara Parks Commission (NPC) transformed the power plant, dormant for a decade, into an attraction centering around “offering visitors an educational experience about Ontario’s power-generating history, and a new perspective on the falls through a new viewing platform.”. The attraction allows visitors to access the main floor housing the alternators and breakers as well as a glass elevator taking visitors 180 feet below the powerhouse to the tailrace tunnel where, after a long walk, you can experience one of the best views of the falls! On the elevator ride you can see the pentstock for unit #1 on one side and one of the massive vertical shafts for unit #2 on the other (I rode it twice just to see it all again). Also visible is the tunnel and tailrace which once carried water from the turbines back to the Niagara river (I had never seen this on prior visit to the plant, of course, since when operating there would have been an awful lot of water in there!).

Hats-off to the NPC as it finally looks as if the majestic plant will be saved for future generations to visit (and for those who have been asking if they can see the insides of the plant: here’s your chance).

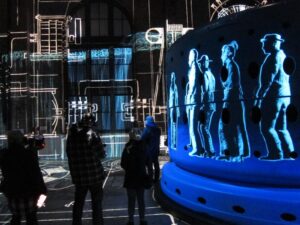

Check out the Niagara Parks site and if you’re in the falls area … you might consider a visit. While the plant is something to behold (although I’d seen it in actual operation), and the tunnel was surprisingly interesting to see (I overheard another visitor commenting on how awestruck they were that this was all dug over 100 years ago with primitive tools) but in addition to this the NPC has added a nighttime light show called “Currents”.

Check out the Niagara Parks site and if you’re in the falls area … you might consider a visit. While the plant is something to behold (although I’d seen it in actual operation), and the tunnel was surprisingly interesting to see (I overheard another visitor commenting on how awestruck they were that this was all dug over 100 years ago with primitive tools) but in addition to this the NPC has added a nighttime light show called “Currents”.

The show starts with interactive projections that follow visitors as they move, then the generating hall comes alive as a story is presented following water and how its power was harnessed. OK, it was a bit “artsy” (I’m an engineer after all) but it was entertaining and really shouldn’t be missed: the show was a high-point of my earlier visit to the attraction – a definite “must see”.

The Author

I hope you enjoyed this rare tour of a 1900’s generating station. A professional engineer and a retired professor at Niagara College in Canada, my personal interests extend to the history of technology, hence why this place was so intriguing! If you have any comments, feel free to contact and please refer to the ‘Rankine’ station on the subject line.

Other tours of Niagara generating stations on this site include the Sir Adam Beck 1 Generating Station, an old 25Hz station from 1922 which has undergone a complete update to 60Hz as well as the Decew Falls Generating Station 110 years old and still operating in Niagara. This plant has the distinction of operating at the relatively high frequency of 66.7Hz in a time when other plants were running at 25Hz.